A Testing Solution That Works

The gold standard method to identify this sort of miswired outlet device is to use a voltmeter connected to a known good earth ground to test each hot, neutral, and ground conductor in all outlets.

But in reality, this type of test isn’t done except perhaps as part of a post-accident forensics investigation.

However, a simple test is to check the outlet with a mid-voltage non-contact capacitive voltage tester (90- to 1,000-volt range), commonly referred to as an non-contact voltage tester (NCVT).

When this tester is used on a properly wired outlet, you’ll hear a beep or see a light only when its tip is inserted in the “hot slot” of an outlet, but when it gets anywhere near the front or ground contact of an RPBG miswired outlet, it typically beeps/lights from inches away, because the internal ground strap in the outlet will be biased to 120 volts, which provides a large electrified surface area (Figure 5).

The green light on the left and center outlets indicates no or low-voltage (under 40 volts), while the red light on the right outlet indicates a hot ground condition (typically more than 40 volts for most standard sensitivity NCVTs). Although using a DMM to test between a known earth ground to each outlet contact is the gold standard, adding this NCVT check for RPBG outlets to your test procedure could save lives and dollars.

Interconnected Outlet Fault Currents

While the shock hazard created by a reverse polarity bootleg ground (RPBG) outlet is bad enough, if multiple appliances or gear are plugged into separate electrical outlets – one of which is wired incorrectly as a RPBG – then any signal or control cable between the appliances will be subject to short circuit fault currents between the correctly wired outlet’s ground and the RPBG outlet’s ground, which is actually connected to the incoming hot wire.

Because these signal cables are typically small diameter (22 gauge), they don’t offer a low enough impedance to created sufficient fault current that will trip a 15- or 20-amp circuit breaker.

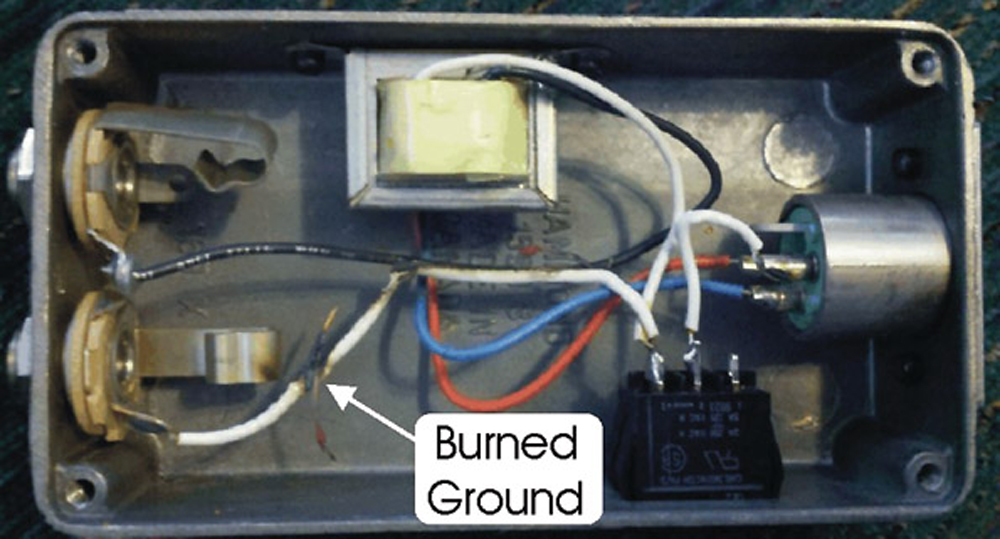

The interconnecting gear often becomes the “fuse” heating up red hot before a wire or circuit board trace melts and opens the ground fault path.

It’s important to note that this equipment failure does not remove the electrocution hazard, given the fact that a technician handling the gear will be still be touching a chassis that is directly connected to the incoming 120-volt line.